How drivers can benefit from Volvo Dynamic Steering

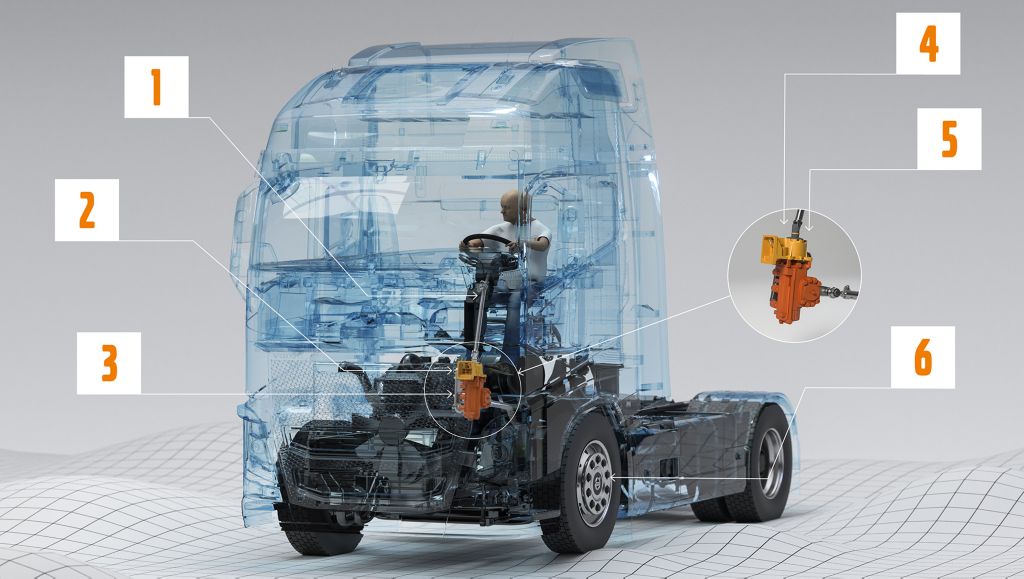

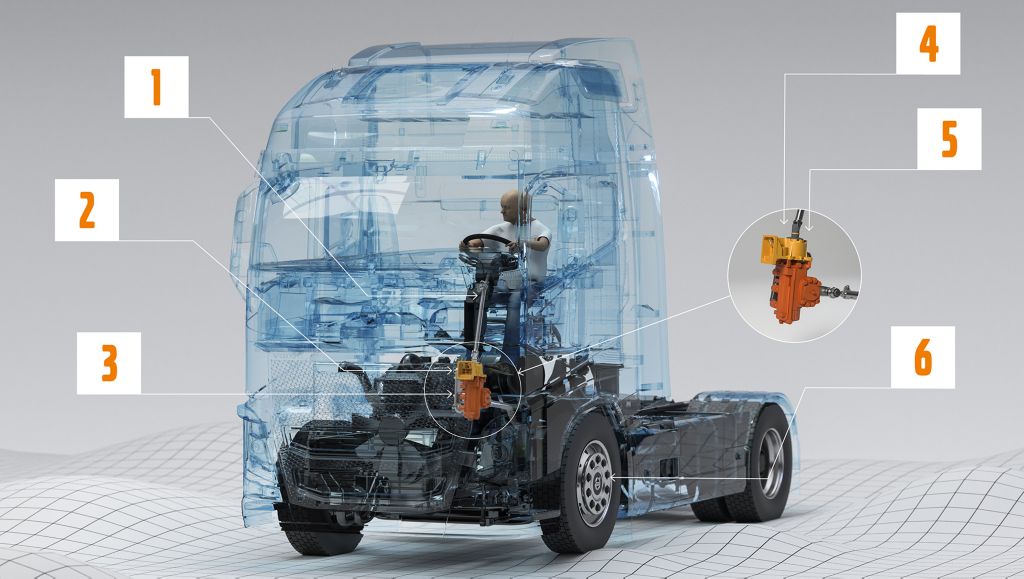

1. Steering rod

It has been modified to accommodate the new installation.

2. Control unit

Information on the movement of the truck, such as its speed, is collected and processed by the control unit. It then sends signals to the electric motor, which corrects the steering force the driver feels.

3. Hydraulic steering gear

The electric motor twists a torsion rod in the hydraulic steering gear. The more the torsion rod is twisted, the more a hydraulic valve is opened, which increases the hydraulic assistance.

4. Electric motor

An electrically controlled motor is fitted on top of the steering gear, and the two work together. The motor is controlled 2,000 times a second to harmonise steering-wheel power, and has an output torque of maximum 25 Nm.

5. Internal sensor

The internal sensor is inside the electric motor and is designed to measure the angle and drivers’ applied torque. This data is needed to calculate how the system can create the perfect steering response.

6. External sensors

The truck acts on information that is gathered from different sensors that are spread throughout the truck. It then combines this to describe the exact ambient conditions.

Less surface disturbances from the road

VDS automatically compensates for unevenness in the road surface and eliminates vibration and involuntary steering wheel movement.

Lighter steering

When driving at low speeds, steering is about 75 per cent lighter. Drivers are therefore able to handle tight cornering, roundabouts and other demanding manoeuvres in a far safer and more relaxed way.

Improved directional stability

At higher speeds, the truck maintains directional stability even if the road surface is uneven, and helps the driver to balance direction deviation. This is an important safety aspect on the highway.

Easier to reverse

While the truck is in motion, the steering wheel automatically returns to the dead-ahead position when the driver lightens his or her grip on the wheel. This works just as well when reversing, which therefore is made a lot easier.

Less muscle strain

VDS cuts muscular strain by 20 to 30 per cent, and for certain manoeuvres by up to 70 per cent*. This allows truck drivers to avoid repetitive strain injuries and extend their professional careers.

Safer driving

Since the system compensates for all small bumps in the road, the driver becomes more relaxed and thus less tired. This improves safety out on the road.

* The study behind these figures was carried out by VTI, the Swedish National Road and Transport Administration.